A supply chain certification can be a great way of proving that you are an expert in your field. A credential like the CSCP will make your employer more attractive and set you apart among your peers. It will make your organization more competitive in today's economic environment. Here are some benefits to becoming certified in supply-chain management.

CSCP is an end of-end supply-chain certification

The CSCP certificate is a valuable credential that supply chain professionals can use to gain a deeper understanding and a better ability to visualize the entire supply chain. The complexity of supply chain activities is complex. The CSCP certification assesses the candidate's ability to coordinate and integrate these activities. Companies are searching for supply chain professionals with the ability to add value at every stage of the supply cycle.

The CSCP certification exam consists 8 modules that cover key aspects of supply-chain management. The questions in the exam are divided into two parts, with the first three focusing on knowledge of the curriculum. The last two parts are to test the candidates' ability to prepare for the final exam. The exam range is from 200 to 350 points, and a score of 300 or higher is considered a pass. Scores below 300 are considered failing.

CPSM (Certificate of Supply Chain Management) is a specialized certification for supply chains.

The CPSM (Certified Professional in Supply Management) credential is one of the most well-known and widely respected supply chain certifications. The Institute for Supply Management issues it. It is the largest supply management organization in the world. International recognition is granted to CPSM certificates.

The CPSM certification stands for Supply Management Professionals as a mark of excellence. The certification consists of three modules that require advanced knowledge and skills. This certification is for supply management professionals who want to implement supply chains strategies in their organizations. It takes six to twelve months to complete the certification program. Successful candidates will need to renew their credential each three years.

CSCP requires four-year undergraduate degree

A CSCP certification, or Certified Supply Chain Professional, demonstrates that an individual has advanced knowledge and experience in supply chain management. This credential distinguishes an individual from others and proves that they are an expert in their field. There are many options to choose from if you are interested in getting this certification.

For the CSCP exam, you must have three years of work experience. You also need a bachelor's. For CSCP certification to be maintained, students must accumulate 75 professional development point every five years. Students will need another 75 points to retake their exam.

Supply chain certification: Retake fees

Multiple-choice online certification exam Certified Supply Chain Fundamentals(tm). You can take the test anywhere in the world. It consists of 50 multiple-choice questions. To earn certification, you need to score 70% or more on the test. There are fees of $450 for a retake.

For you to be eligible for this exam, your work experience must include a decision-making role. A decision-making position is any job where you are responsible for controlling processes or defining tasks. This could include a managerial or supervisory job. ASQ certifications can also be applied to Supplier Quality Professional exams.

FAQ

How can manufacturing prevent production bottlenecks?

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes both quality control and capacity planning.

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It emphasizes consistency and eliminating variance in your work.

Why is logistics so important in manufacturing?

Logistics is an integral part of every business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What does the term manufacturing industries mean?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They create goods from raw materials, using machines and various other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

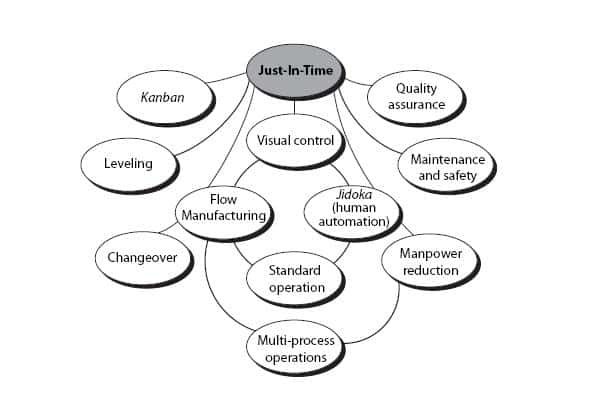

How to use the Just In-Time Production Method

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's a way to ensure that you get the right resources at just the right time. This means that only what you use is charged to your account. Frederick Taylor, a 1900s foreman, first coined the term. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. You won't have to pay more for unnecessary items.

There are several types of JIT techniques:

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. This will allow you to calculate how long it will take to make more.

-

Inventory-based : You can stock the materials you need in advance. This allows you to forecast how much you will sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT : This is probably the most popular type of JIT. You assign certain resources based off demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This is very similar to cost-based but instead of looking at total costs of the company you are concerned with how many raw materials you use on an average.

-

Time-based: Another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It is essential because it reduces lead-times and increases throughput.