An industrial engineer's job description is to design and implement processes that eliminate wastefulness and optimize resource utilization. These engineers work in various industries to design processes that benefit their companies in a variety of ways. They look at production schedules, design specifications, as well as workflows to help create more efficient processes. Additionally, industrial engineers help to improve the profitability of production processes. They also contribute to improving the quality of services and products.

Job requirements for industrial engineer

The role of an Industrial Engineer is crucial in a manufacturing organisation. This person uses innovative design methods to create efficient operations for the natural or organic food industries. This person develops meticulous solutions to meet the needs of internal customers and leads dynamic projects to improve the manufacturing process. A person must be competent and capable of performing all required duties in order to be eligible for this job. Industrial engineers must be skilled in AutoCAD and Pro-E.

Industrial Engineers focus on the development and testing of integrated systems that maximize efficiency. Apart from that, the job also requires you to study human work factors in order maximize product quality. Other responsibilities include logistics and cost analysis as well as guest coordination. In addition, this person must be proficient in advanced technical skills such as Microsoft Office. Additionally, you will need to have knowledge in systems design, logistics, and manufacturing. You must possess the technical skills to do your job well in Orlando.

Industrial engineer's salary

You should look at the salaries for Industrial & Manufacturing Engineers here in Orlando, FL if you are considering a career in this field. Orlando is one the best places in America, with an average annual salary of $803,325 This is 6% lower than the national average, and 9% less than the New York average salary. Orlando's median salary range is $64,260 - $96,390. With the middle 67% earning $85,000 annually and the top 10% earning $102,000, the average Orlando worker earns $64,260.

Salaries for Industrial Engineers in Orlando can range from $89,700 USD to $114,300 USD. As with any career, the salaries for industrial engineers vary. The salary figures listed above are based on the average salary for an Industrial Engineer with five to ten years of experience. However, people with more experience will make nearly twice the amount of those with less. But, pay scales can vary between industrial engineers.

Responsibilities of industrial engineer

You will be responsible to design the most efficient process and implement strategies that improve them. You will have to devise and implement efficient, flexible and effective processes to meet customer requirements and achieve business goals. The Industrial Engineer is responsible for many tasks such as Process Improvement, Capacity Planning and Reporting, Cost Analysis, Data Analysis, Capital Project Management and Discrete Events Simulation. The Industrial Engineer will also need to assist with cross-functional improvement efforts by carrying out observations and time studies.

Strong communication skills are required, as well as engineering experience and a strong grasp of statistical analysis, to be able do this job. Managers will be closely involved in the development of design standards for industrial engineers and leading moderately difficult projects. They will analyze data and create statistical reports to improve process flow, standard times, and quality. They will coordinate key studies and produce key metric reports, including process documentation and production reports.

FAQ

How important is automation in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It enables them to provide services faster and more efficiently. It also helps to reduce costs and improve productivity.

What is the job of a production plan?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They ensure that the product or service is of high quality and meets client requirements.

Why should you automate your warehouse?

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automating warehouses is a great way to save money. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety enhancements

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

Workers are more productive

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

You can be sure that high-quality products will arrive on time

-

Removing human error

-

This helps to ensure compliance with regulations

What does manufacturing mean?

Manufacturing Industries are those businesses that make products for sale. The people who buy these products are called consumers. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

Is it possible to automate certain parts of manufacturing

Yes! Yes. The wheel was invented by the Egyptians thousands of years ago. We now use robots to help us with assembly lines.

There are many uses of robotics today in manufacturing. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

There are many other examples of how manufacturing could benefit from automation. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

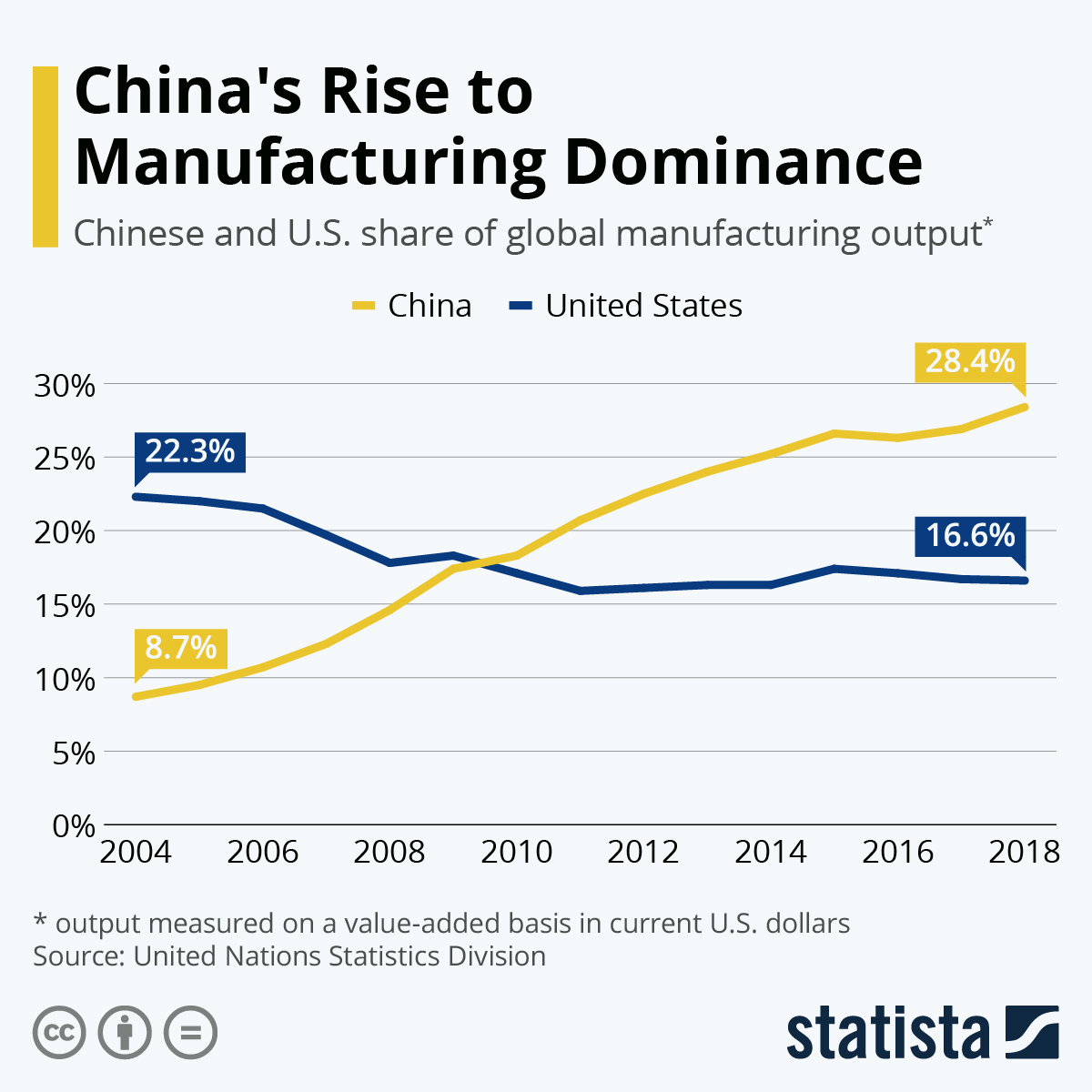

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands in for "Sort", the "Set In Order", "Standardize", or "Separate". Toyota Motor Corporation invented the 5S strategy in 1954. It improves the work environment and helps companies to achieve greater efficiency.

This method has the basic goal of standardizing production processes to make them repeatable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. These actions allow workers to perform their job more efficiently, knowing what to expect.

Implementing 5S requires five steps. These are Sort, Set In Order, Standardize. Separate. And Store. Each step is a different action that leads to greater efficiency. For example, when you sort things, you make them easy to find later. When you set items in an order, you put items together. You then organize your inventory in groups. Make sure everything is correctly labeled when you label your containers.

Employees will need to be more critical about their work. Employees should understand why they do the tasks they do, and then decide if there are better ways to accomplish them. They will need to develop new skills and techniques in order for the 5S system to be implemented.

The 5S method increases efficiency and morale among employees. They are more motivated to achieve higher efficiency levels as they start to see improvement.