CEVA Logistics is an organization that offers logistics services. These logistics companies offer several benefits to their employees. Here's how you can apply to a logistics job at one of these companies. First, you can search by location for job opportunities.

Job description

CEVA Logistics offers many jobs to individuals with diverse education and experience. The company's core values are dedication to customer service and on-time delivery. The company also seeks individuals who are passionate about logistics and who are willing to work hard. For a job, applicants who have prior experience or who can demonstrate a positive attitude and have some knowledge in logistics will be given preference.

CEVA Logistics is searching for a Process/Industrial Engineering to develop and implement new processes, and increase efficiency. The ideal candidate should be energetic and self-motivated. They must also be able to work in collaboration with staff at the plant. They are responsible for designing and implementing process plans, managing projects, as well as using modeling and analytical skills. They should also be skilled in robotics and other manufacturing processes, which will increase quality and efficiency.

Education necessary

Applicants interested in working for CEVA Logistics can choose from a wide range of career opportunities, such as sales rep or warehouse manager. They have the option to become operations managers, which involves managing the day-today operations, including inventory scheduling and customer service. These positions are often accompanied by a team. This position requires a bachelor's in logistics and supervisory experience.

The online application process is easy for interested candidates. To apply online, candidates first need to create a profile with the company's career portal. To connect to their LinkedIn profile, they can attach their resumes and other relevant information. Once their profile has been completed, they are able to choose their preferred country and get in contact with a recruiter.

Salary range

If you are interested in applying for a CEVA Logistics career, the first thing to do is create a profile at the company's online job portal. This will allow you to connect with LinkedIn and upload your resume. You can also manually input information about skills, experience, and any other pertinent information. Next, choose the region or country you'd like to work. Once you have done this, you will receive contact information from the recruiter for that region.

CEVA Logistics has a variety of salaries. These vary depending on your job title, work experience, and geographic location. A Vice President at CEVA Logistics is paid $166,000 per year, while an Air Break Bulk Specialist receives $24,000. But, the economic climate in each region can mean that salaries may vary.

Locations

If you're looking for a great career in logistics, consider a position with CEVA Logistics. The company has a number of different positions, each with its own responsibilities and qualifications. To apply for a specific job, just type the job title in search box along with your location. If you search for Edison, NJ jobs, you will see the listings. You'll need to have experience in driving, and must be able to communicate well with internal and external customers, as well as perform a variety of other tasks.

CEVA Logistics has many job opportunities, including supervisory posts. Supervisors are responsible for the company's day to day operations. Supervisors manage inventory, coordinate schedules, oversee employees' activities, and monitor their performance. They typically supervise a team of employees and usually require a bachelor's or similar experience. It is also important to have strong leadership and management abilities.

Applying online

If you're in the market for a job in the logistics industry, you can apply online for a position with CEVA Logistics. Ceva Logistics was formed in 2006 from the merger between two Australian and Texan contract logistic companies. Its operations now span over 950 locations in 170 different countries. You have the option to apply for part or full-time employment.

Although some positions at CEVA may require some experience in order to be successful, many are entry-level. Others require minimal to moderate experience. Some of the more entry-level positions include customer service representative, admin clerk, and dispatcher.

FAQ

What are the responsibilities for a manufacturing manager

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They should also be aware of any problems within the company and act accordingly.

They should also know how to communicate with other departments such as sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

What does "warehouse" mean?

Warehouses and storage facilities are where goods are kept before being sold. You can have it indoors or outdoors. It may also be an indoor space or an outdoor area.

How can excess manufacturing production be reduced?

Better inventory management is key to reducing excess production. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. By doing this, we could free up resources for other productive tasks.

This can be done by using a Kanban system. A Kanban board can be used to monitor work progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state is assigned a different priority.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This helps to keep work moving forward while ensuring that no work is left behind. A Kanban board allows managers to monitor how much work is being completed at any given moment. This allows them to adjust their workflows based on real-time information.

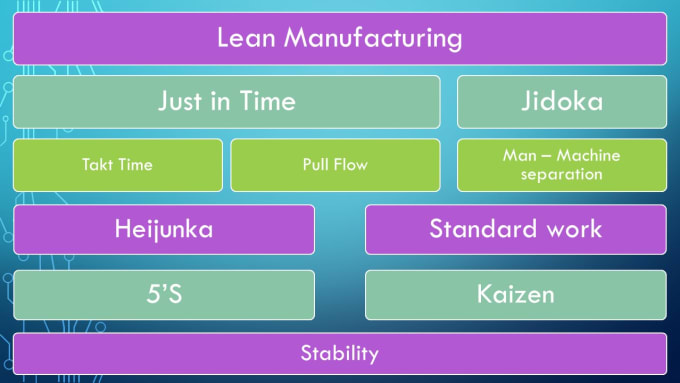

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does nothing to add value to a product is waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Material surplus

These ideas can help manufacturers improve efficiency and reduce costs.

What are the 4 types manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

What skills are required to be a production manager?

Production planners must be flexible, organized, and able handle multiple tasks. Also, you must be able and willing to communicate with clients and coworkers.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. The main goal of Six Sigma is to reduce variation from the mean value of production. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If you notice a large deviation, then it is time to fix it.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you understand this, you can then identify the causes of variation. Also, you will need to identify the sources of variation. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. Random variations would include, for example, the failure of some widgets to fall from the assembly line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you identify the problem areas, it is time to create solutions. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they don't work, you will need to go back to the drawing boards and create a new plan.