Supply chain certification proves that you're an expert in the field. A credential like the CSCP will make your employer more attractive and set you apart among your peers. It will make your organization more competitive in today's economic environment. These are just a few of the many benefits of becoming certified in supply chain management.

CSCP is an end to-end supply chain certification

The CSCP certification is a valuable credential for supply chain professionals because it provides a broader understanding of the supply chain and helps the candidate to visualize the entire process. The complexity of supply chain activities is complex. The CSCP certification assesses the candidate's ability to coordinate and integrate these activities. Companies are looking to hire supply chain professionals who will add value at every point of the supply-chain.

The CSCP certification exam consists 8 modules that cover key aspects of supply-chain management. The exam questions are split into two sections. The first three focus on curriculum knowledge. The last two parts are to test the candidates' ability to prepare for the final exam. The exam range is from 200 to 350 points, and a score of 300 or higher is considered a pass. A score lower than this is considered a failing grade.

CPSM, a specialized supply channel certification, is a good option.

The CPSM credential, which stands for Certified Professional in Supply Management (Certified Professional in Supply Management), has been a well-respected and highly respected supply management certification. The Institute for Supply Management is the largest supply-management association in the globe. CPSM certification is internationally recognized.

The CPSM certification, which is a benchmark of excellence in supply management, is a standard for excellence. It consists of three modules, each requiring advanced skills and knowledge. Earning this certification will allow supply management professionals to implement supply chain strategies throughout an organization. The certification process can take anywhere from six to twelve month. Successful candidates will need to renew their credential each three years.

CSCP requires four-year undergraduate degree

The CSCP certification, which stands for Certified Supply Chain Professional, shows that an individual is knowledgeable and experienced in supply chain management. The credential sets an individual apart from their colleagues and provides proof that a person is an expert in their field. There are many options to choose from if you are interested in getting this certification.

Three years' work experience and a bachelor degree are required to pass the CSCP test. Students will need to accumulate 75 professional learning points every five year in order for their certification to continue. Students will need another 75 points to retake their exam.

Retake fees are charged for supply chain certification

Multiple choice online certification exam Certified Supply Chain Fundamentals (CSCF(tm).) You can take the test anywhere in the world. It consists of 50 multiple-choice questions. To earn certification, you need to score 70% or more on the test. You will need to pay $450 USD for each retake.

For the exam to be valid, you must have previously worked in a decisionmaking position. A decision-making position is any job where you are responsible for controlling processes or defining tasks. This could be a managerial or supervisory position. If you have other certifications from ASQ, they can also be applied to the Supplier Quality Professional exam.

FAQ

What is the responsibility for a logistics manager

Logistics managers make sure all goods are delivered on schedule and without damage. This is accomplished by using the experience and knowledge gained from working with company products. He/she should also ensure enough stock is available to meet demand.

What is manufacturing and logistics?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What are the jobs in logistics?

There are different kinds of jobs available in logistics. Some examples are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Statistics

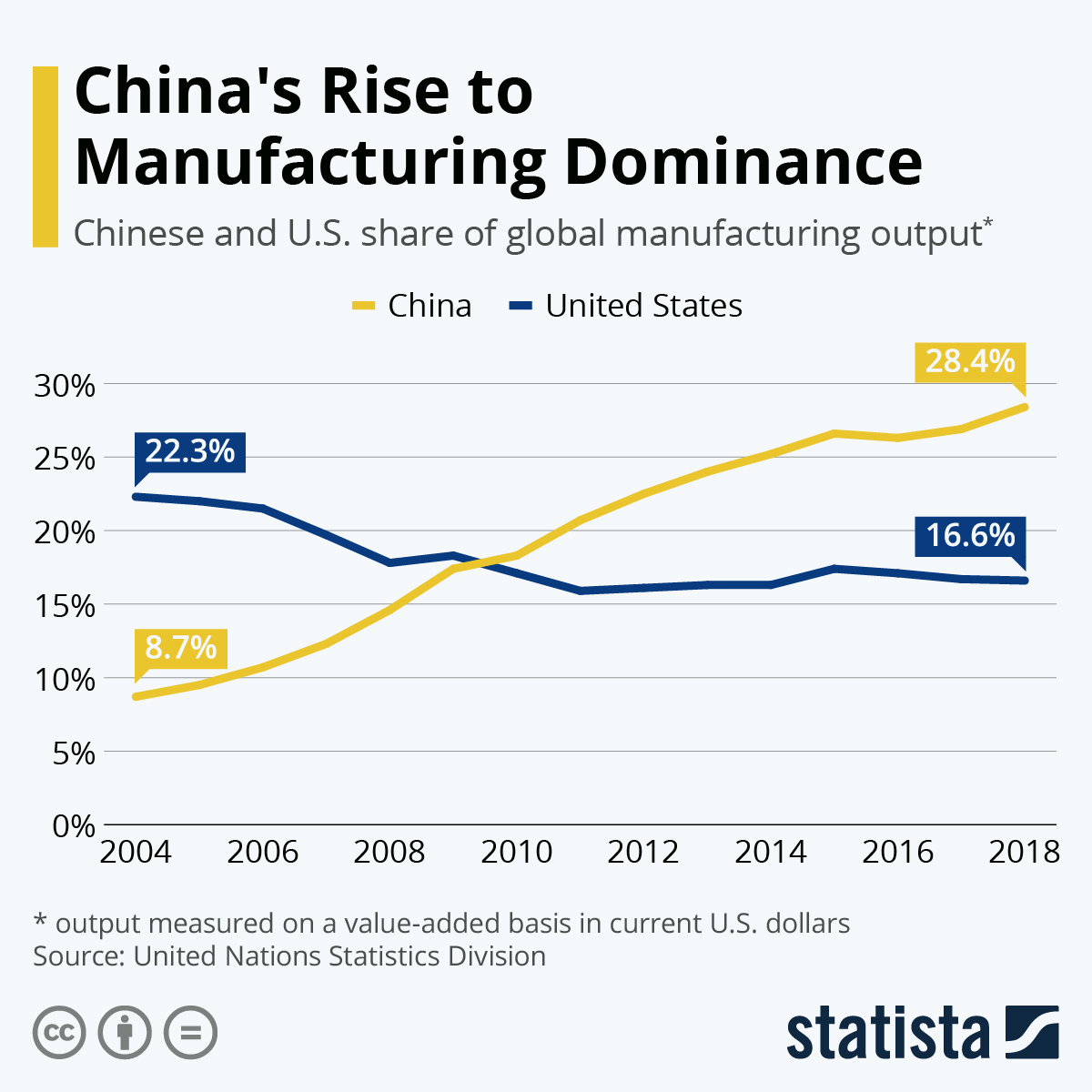

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing practices are widespread in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Lean manufacturing is based on five principles:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

Any aspect of an enterprise can benefit from Lean manufacturing. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types:

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.