The career of biomedical engineer can have a positive effect on people's health. These engineers work in a wide range of fields, including pharmaceutical manufacturing, health care facilities, and laboratories. Engineers create new products and techniques that benefit patients.

A bachelor's degree in biology is necessary to be a medical engineer. Biomedical engineers must also have a solid foundation in math and science. Additionally, they should have excellent problem-solving skills as well as strong analytical abilities. They can also take internships to gain experience. Sometimes employers will require a master's in order to hire them.

Biomedical engineers are expected to be in high demand due to the aging population as well as advances in medical technology. Biomedical engineers are professionals who work in medical fields to create and test new technologies. Medical equipment can also be designed, manufactured, and repaired by biomedical engineers. They are able to work for medical equipment sales and research companies as well as healthcare facilities.

Biomedical engineers combine science and math to create equipment and computer software that solves biological science problems. They use advanced math and statistics to build complicated medical devices. Biomedical engineers are also responsible, in addition to developing new devices and processes for patients, for testing and approving new medication and drug therapies. They are responsible for ensuring medical equipment performs at its peak performance.

There is a high demand in biomedical engineering, just like any other engineering field. The field is expected increase at a faster rate that other engineering specialties. According to BLS, the number of biomedical engineer jobs will rise by 6 percent between 2020 and 2030 according to the Bureau of Labor Statistics. This is significantly faster than the average rate of growth for all occupations. Biomedical engineers had approximately 15,700 jobs as of 2010. The BLS predicts that there will be 1,400 openings each year through 2029. These openings will be available in the healthcare and medical equipment and supply manufacturing industries as well as research services.

Internships can be a great opportunity for those who are interested in a career as biomedical engineers. These internships give you the chance to learn from real-world biomedical engineers and get hands-on experience. If you are a student, it's a good idea also to take courses such as computer programming, mechanical drawing, and drafting. If science is your passion, you can choose to study anatomy, physiology, and molecular Biology.

People who wish to become a biomedical technician should prepare for this career from high school. Although a bachelor's is a must, employers will prefer a masters. A master's degree in biomedical engineering can open up new opportunities and allow you to assume supervisory positions within the field.

The courses required of biomedical engineers include physics, biology (chemistry), mathematics and maths. During their undergraduate years, biomedical engineering students study subjects such as human anatomy, molecular biology, physiology, and pharmacology. They also complete capstone projects which integrate their engineering skills and solve problems related to biology.

FAQ

What kind of jobs are there in logistics?

Logistics can offer many different jobs. Here are some:

-

Warehouse workers: They load and unload trucks, pallets, and other cargo.

-

Transportation drivers – These drivers drive trucks and wagons to transport goods and pick up the goods.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents - They buy goods and services that are necessary for company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

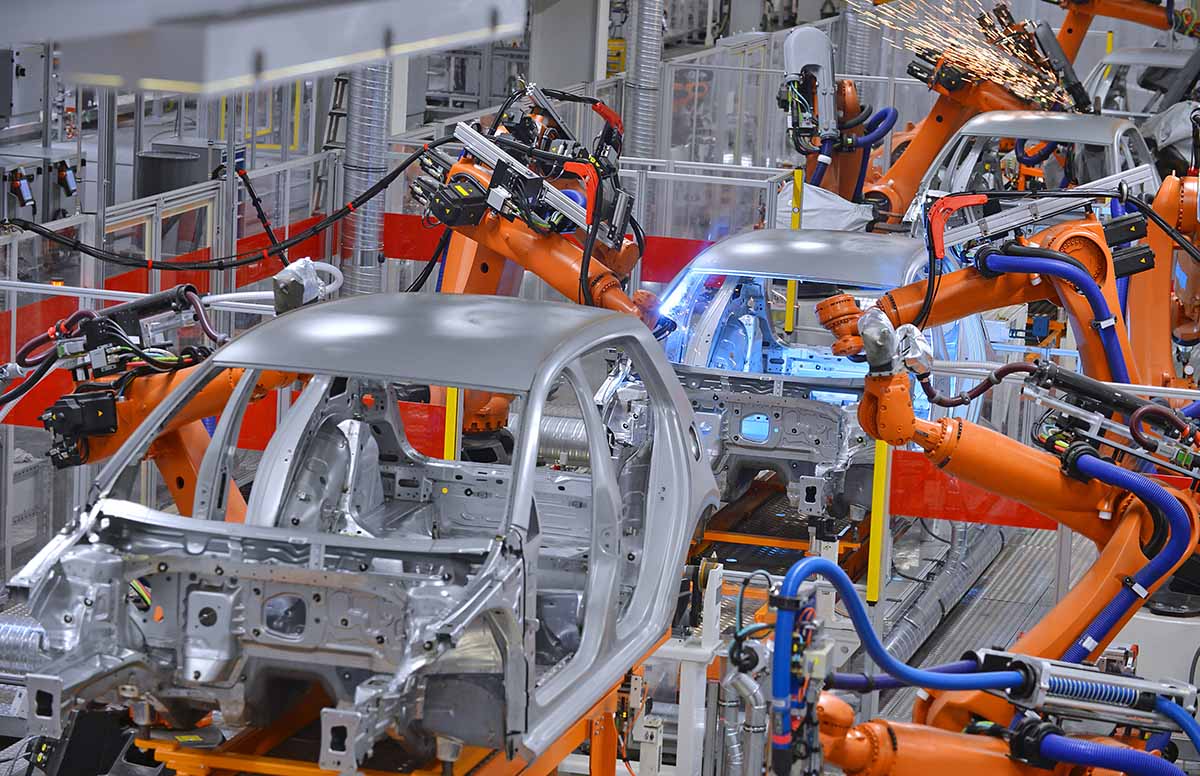

Why automate your factory?

Modern warehousing is becoming more automated. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

It makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

Quality products delivered on time

-

Eliminates human error

-

It helps ensure compliance with regulations

What is the responsibility of a logistics manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is accomplished by using the experience and knowledge gained from working with company products. He/she must also ensure sufficient stock to meet the demand.

What makes a production planner different from a project manger?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use the Just-In-Time Method in Production

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. It allows you to get the right amount resources at the right time. This means that you only pay the amount you actually use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. He observed how workers were paid overtime if there were delays in their work. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You can anticipate problems and have enough equipment and people available to fix them. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will enable you to keep track of how much material is left after you use it. This will allow you to calculate how long it will take to make more.

-

Inventory-based : You can stock the materials you need in advance. This allows for you to anticipate how much you can sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This is the most popular form of JIT. You assign certain resources based off demand. You might assign more people to help with orders if there are many. You'll have fewer orders if you have fewer.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on how much each employee costs, you focus on how long it takes to complete the project.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT : This is the newest type of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It is the process that schedules the delivery of components within a short time of their order. It is essential because it reduces lead-times and increases throughput.