Customers expect products to provide a holistic experience. To fulfill that expectation, companies will need to have a supply network that can deliver personalized, fast, and customized products. Modern supply chains are more flexible and responsive to changing needs than their traditional counterparts. Companies can monitor disruptions, analyze data, and make better decisions to ensure prompt and reliable deliveries.

Accenture Strategy, a service offered by Accenture, assists companies in transforming their supply chain capabilities. This includes creating innovative solutions and accelerating the skills of the supply-chain workforce. It also aligns operating models with business strategy. It also includes a commitment to sustainability and governance. Ultimately, the company aims to build long-term value for its clients.

Accenture's focus is on global supply chain improvement. Accenture combines industry knowledge with digital services to help achieve this goal. Combined with a global supply network, they can help companies build intelligent supply chains that drive profitable growth and positive social change. Accenture's supply chain experts work in a variety of industries, including energy and consumer packaged goods. Accenture's supply chain experts can help clients design, operate and transform their supply chains using a variety of applications and services.

Accenture works with clients to develop sustainability initiatives. They have a global supplier inclusion program that aims to help more companies make good business decisions while advancing a sustainable, inclusive, and ethical supply chain ecosystem. The company recently released a report that provides advice on creating a sustainable supply chain, leveraging data, and leveraging governance. This report includes data about supplier scoring and suggestions for creating resilient supplies networks.

Accenture's supply chains analytics team works with clients, helping them improve sustainability practices and encourage responsible behavior. They are able to help clients identify their strengths, weaknesses, and opportunities for improvement, and design and implement solutions to help them become more resilient. Blue Yonder technology helps companies optimize and build their supply chains.

Accenture has significant purchasing power and supply chain expertise. Accenture developed an enterprise business model in 2007 that allows businesses to better manage their supply chains. Before Accenture, companies were unable to see beyond a few suppliers and had little knowledge about their supply chains. Companies could not respond quickly to changing demand. myConcerto, a company-wide solution that gives companies detailed information about how to monitor their supply channels, was created by the company.

Accenture works with the Defense Logistics Agency, where they help improve the reliability and efficiency in military supply chains. The DLA handles 520,000 shipments each year and averages 8,000 contracts every day. Accenture collaborates closely with the DLA for product availability and faster delivery times. Accenture also collaborates with Coles Supermarkets in order to improve customer service and create a Splunk-based control tower monitoring solution.

FAQ

Is automation important in manufacturing?

Automation is important not only for manufacturers but also for service providers. Automation allows them to deliver services quicker and more efficiently. It also helps to reduce costs and improve productivity.

How does a Production Planner differ from a Project Manager?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

Is it necessary to be familiar with Manufacturing Processes before we learn about Logistics.

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

What are the 7 Rs of logistics?

The acronym "7R's" of Logistics stands for seven principles that underpin logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The following letters make up the acronym:

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful – Treat others fairly and equitably.

-

Reliable - Find ways to save money and increase your productivity.

-

Recognizable - provide customers with value-added services.

Are there ways to automate parts of manufacturing?

Yes! Automation has been around since ancient times. The Egyptians discovered the wheel thousands and years ago. We now use robots to help us with assembly lines.

Robotics is used in many manufacturing processes today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

Manufacturing can also be automated in many other ways. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

What is the job of a logistics manger?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

Why automate your warehouse?

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. Technology investment is necessary to enable warehouses to respond quickly to changing demands. The benefits of automating warehouses are numerous. These are just a few reasons to invest in automation.

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety is boosted

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

Makes workers more efficient

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

Ensures quality products are delivered on time

-

Human error can be eliminated

-

Assure compliance with regulations

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

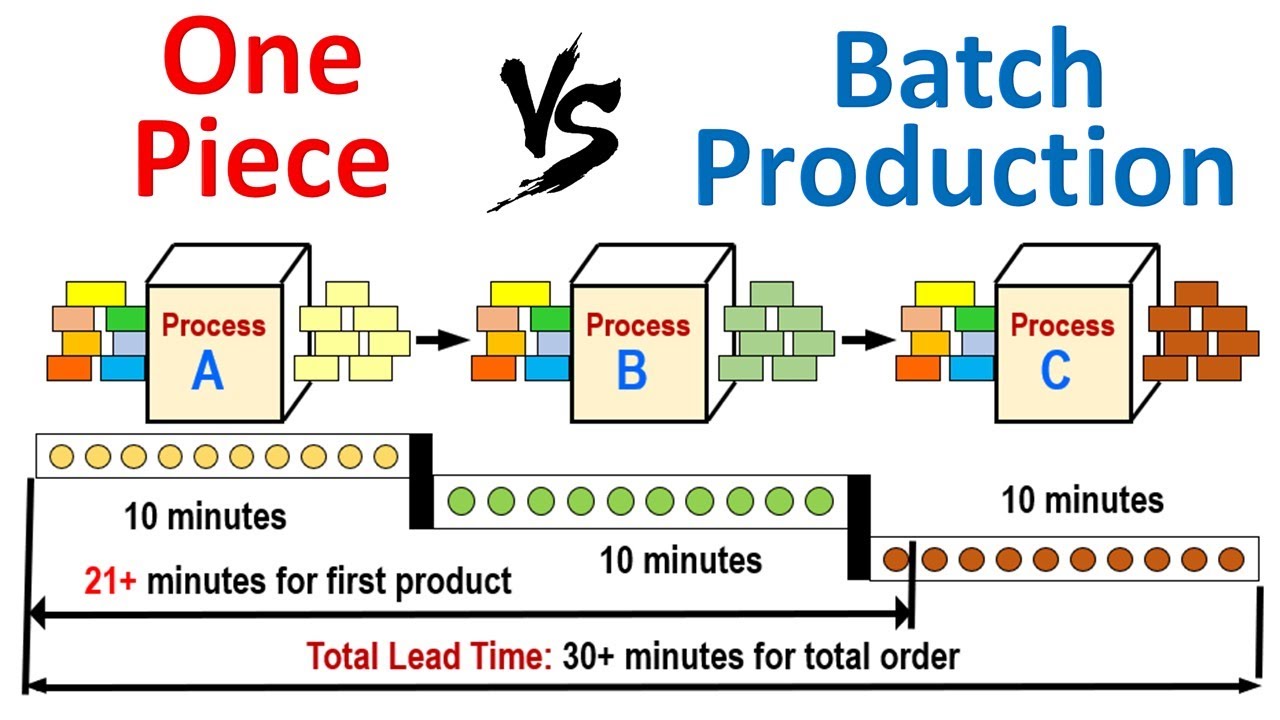

How to Use the Just In Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It is a process where you get the right amount of resources at the right moment when they are needed. This means that you only pay for what you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. He observed how workers were paid overtime if there were delays in their work. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You will have the resources and people to solve any problems you anticipate. This way, you won't end up paying extra money for things that weren't really necessary.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will enable you to keep track of how much material is left after you use it. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you predict the amount you can expect to sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This is the most popular form of JIT. This is where you assign resources based upon demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: Another variation of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based: This is one of the newest forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. This is used to increase production and minimize inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important as it reduces leadtimes and increases throughput.